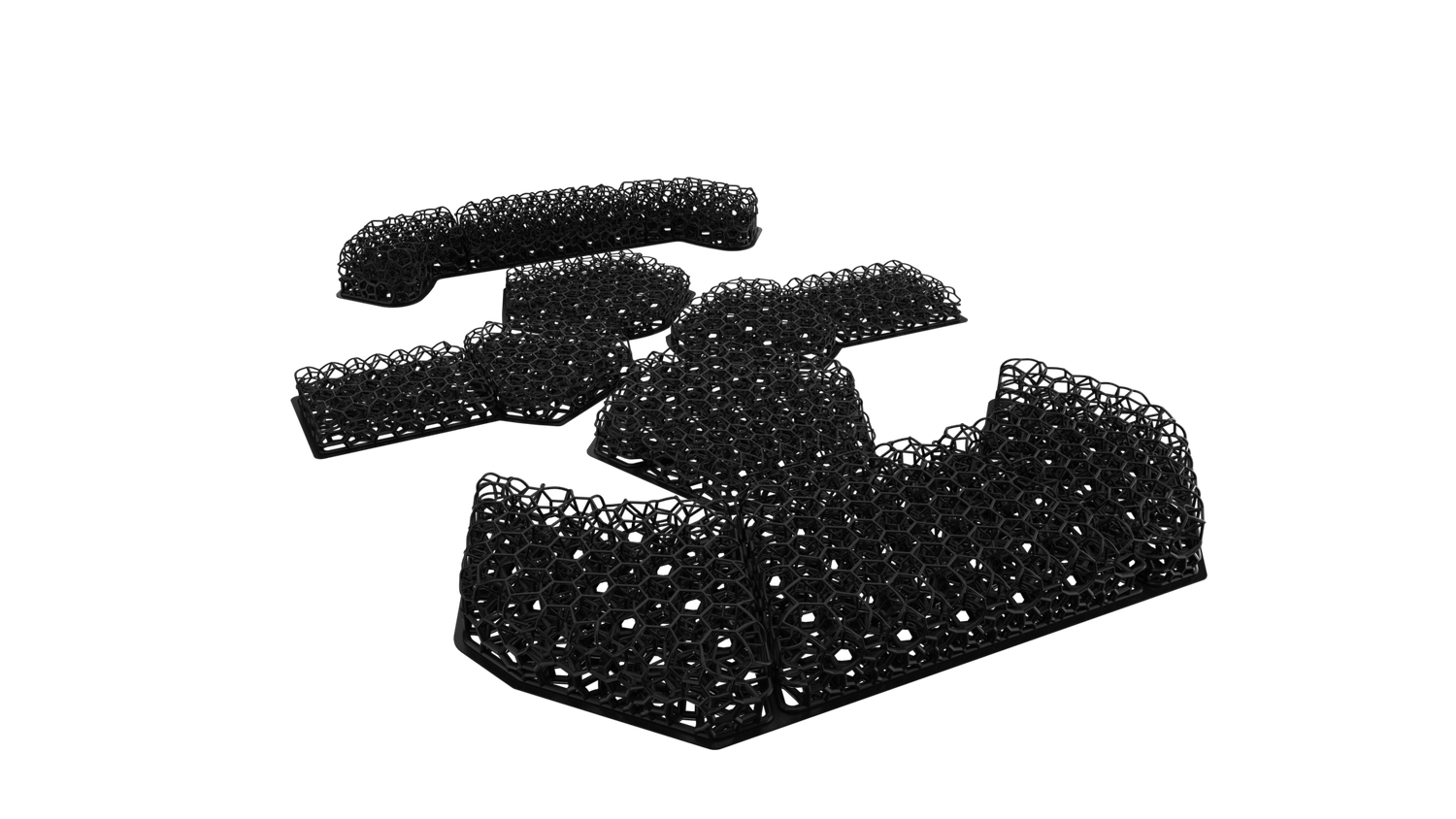

HHV Micro Lattice Helmet Pads (For ATE, FAST, MICH, ACH,ECH)

We are excited to finally offer our Micro Lattice helmet pads for tactical or ballistic helmets. These pads have been in development for years and through our partnership with Carbon® and their Digital Light Synthesis ™ manufacturing process we are able to create energy absorbing complex structures in a helmet pad that could never be manufactured before.

These micro lattice pads average single digit deformation numbers when tested to 1400 fps with 9mm projectiles on our ATE ballistic helmet (click for test data). Regardless of whether they are at -60 degrees or 160 degrees they still perform the same. This can not be said for standard foam pads

The Carbon DLS™ process enables lattice structures that absorb and dissipate energy through the precise tuning of strut thickness and cell size.

Couldn't load pickup availability

SHIPPING & RETURNS

Same-Day Shipping on in-stock items: Place your order before the daily cutoff time, and we'll ship it out to you on that very day. In cases where a product is out of stock, we take pride in offering faster lead times than our competitors, so you can still expect a speedy delivery.

Exchanges & Returns: Be sure to inspect your new helmet carefully when you receive it — if you notice any defects or are dissatisfied with it for any reason, send it back to us within 30 days for a hassle-free exchange or refund.

WARRANTY

- Lifetime Warranty on Hard Components

- 1-Year Warranty on Soft Components

Please note that our warranty does not cover normal wear and tear, misuse, abuse, or improper storage of your ballistic helmet.

HHV Micro Lattice Helmet Pads (For ATE, FAST, MICH, ACH,ECH)

So comfy. WAY better than the stock padding and more breathable!

Incredibly Awesome, Gear and service!! Top Notch!!

Breat product breathable and grippy.

The delivery was very fast, and I really appreciated your prompt responses to my inquiries.

Ehhh, it’s good, but I don’t see myself using it for everyday use. Great product though; it just makes the helmet bulky.

Hassle-Free Exchanges & Returns

Return any item in new condition within 30 days, no questions asked.

Same Day Shipping

In stock items ship same day on orders placed before 10:00AM CST.

Lifetime Repairs

We stand by our products, offering a lifetime warranty for hard components.

Fully Tested by Accredited Laboratories

We only use 3rd-party labs accredited by the NIJ or ANSI.

Battle Scars Warranty

If one of our helmets saved your life, we’ll replace it with a new one.